- 您现在的位置:买卖IC网 > Sheet目录861 > GRM43DR61E106KA12L (Murata Electronics North America)CAP CER 10UF 25V 10% X5R 1812

�� �

�

�

�!� Note� ?� Please� read� rating� and� !� CAUTION� (for� storage,� operating,� rating,� soldering,� mounting� and� handling)� in� this� catalog� to� prevent� smoking� and/or� burning,� etc.�

�?� This� catalog� has� only� typical� speci?cations.� Therefore,� please� approve� our� product� speci?cations� or� transact� the� approval� sheet� for� product� speci?cations� before� ordering.�

�C02E.pdf�

�Sep.25,2013�

�!� Caution�

�Continued� from� the� preceding� page.�

�4-3.� Correction� of� Soldered� Portion�

�When� sudden� heat� is� applied� to� the� capacitor,� distortion� caused�

�Table� 3�

�Temperature� Preheating� Temperature�

�(� Δ� T)�

�Iron� Tip�

�by� the� large� temperature� difference� occurs� internally,� and� can� be�

�the� cause� of� cracks.� Capacitors� also� tend� to� be� affected� by�

�mechanical� and� thermal� stress� depending� on� the� board� preheating�

�Part� Number�

�GJM/GQM/GR3/�

�of� Soldering� Differential� Atmosphere�

�Temperature�

�temperature� or� the� soldering� fillet� shape,� and� can� be� the� cause�

�of� cracks.� Please� refer� to� "1.� PCB� Design"� or� "3.� Optimum� solder�

�amount"� for� the� solder� amount� and� the� fillet� shapes.�

�1.� Correction� with� a� Soldering� Iron�

�GRJ/GRM� Series�

�03/15/18/21/31� sizes�

�GRJ/GRM� Series�

�32/43/55� sizes�

�GQM� Series�

�350°C� max.� 150°C� min.� Δ� T� V� 190°C�

�280°C� max.� 150°C� min.� Δ� T� V� 130°C�

�Air�

�Air�

�1-1.� In� order� to� reduce� damage� to� the� capacitor,� be� sure� to�

�preheat� the� capacitor� and� the� mounting� board.� Preheat� to�

�the� temperature� range� shown� in� Table� 3.� A� hot� plate,� hot�

�air� type� preheater,� etc.� can� be� used� for� preheating.�

�1-2.� After� soldering,� do� not� allow� the� component/PCB� to� cool�

�down� repidly.�

�1-3.� Perform� the� corrections� with� a� soldering� iron� as� quickly�

�as� possible.� If� the� soldering� iron� is� applied� too� long,� there�

�is� a� possibility� of� causing� solder� leaching� on� the� terminal�

�electrodes,� which� will� cause� deterioration� of� the� adhesive�

�strength� and� other� problems.�

�2.� Correction� with� Spot� Heater�

�Compared� to� local� heating� with� a� soldering� iron,� hot� air�

�heating� by� a� spot� heater� heats� the� overall� component� and�

�board,� therefore,� it� tends� to� lessen� the� thermal� shock.� In� the�

�case� of� a� high� density� mounted� board,� a� spot� heater� can� also�

�prevent� concerns� of� the� soldering� iron� making� direct� contact�

�with� the� component.�

�2-1.� If� the� distance� from� the� hot� air� outlet� of� the� spot� heater� to�

�22� size�

�*Applicable� for� both� Pb-Sn� and� Lead� Free� Solder.�

�Pb-Sn� Solder:� Sn-37Pb�

�Lead� Free� Solder:� Sn-3.0Ag-0.5Cu�

�Table� 4�

�the� component� is� too� close,� cracks� may� occur� due� to�

�thermal� shock.� To� prevent� this� problem,� follow� the�

�Distance�

�Hot� Air� Application� angle�

�5mm� or� more�

�45°� *Figure� 1�

�conditions� shown� in� Table� 4.�

�2-2.� In� order� to� create� an� appropriate� solder� fillet� shape,� it� is�

�recommended� that� hot� air� be� applied� at� the� angle� shown�

�Hot� Air� Temperature� Nozzle� Outlet� 400°C� max.�

�Less� than� 10� seconds�

�(1206� (3216� in� mm)� size� or� smaller)�

�Application� Time�

�Less� than� 30� seconds�

�(1210� (3225� in� mm)� size� or� larger)�

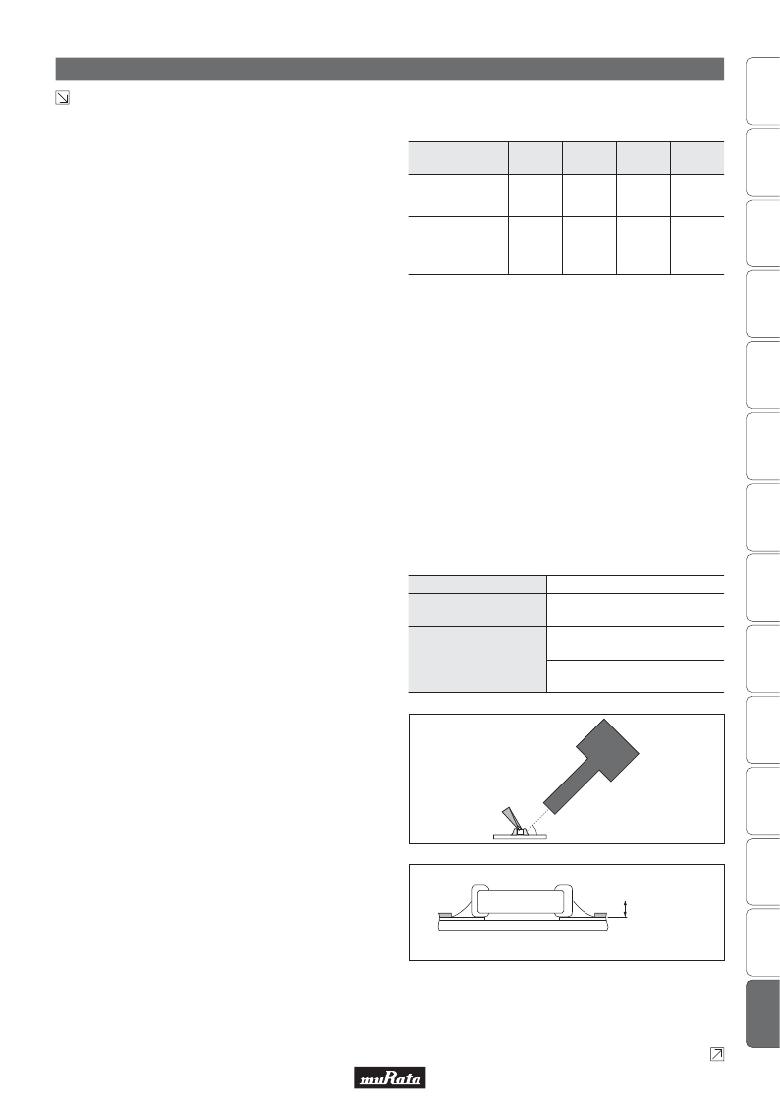

�[Figure� 1]�

�in� Figure� 1.�

�One-hole� Nozzle�

�an� Angle� of� 45°�

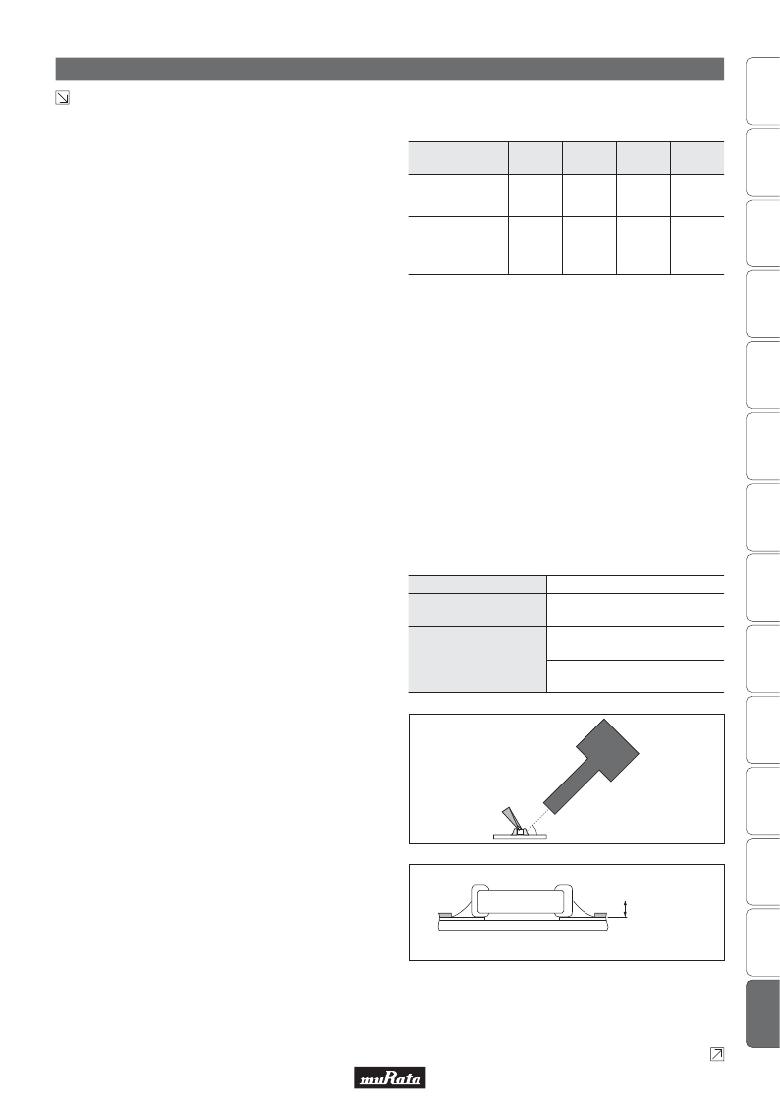

�3.� Optimum� solder� amount� when� re-working� with� a� soldering� iron�

�3-1.� In� the� case� of� sizes� smaller� than� 0603,� (GJM/GQM/GR3/�

�GRJ/GRM� Series,� 03/15/18� sizes),� the� top� of� the� solder�

�fillet� should� be� lower� than� 2� /� 3� of� the� thickness� of� the�

�component� or� 0.5mm,� whichever� is� smaller.� In� the� case�

�of� 0805� and� larger� sizes,� (GJM/GQM/GR3/GRJ/�

�Solder� Amount�

�in� section�

�GRM� Series,� 21/22/31/32/43/55� sizes),� the� top� of� the�

�solder� fillet� should� be� lower� than� 2� /� 3� of� the� thickness� of�

�the� component.� If� the� solder� amount� is� excessive,� the� risk�

�of� cracking� is� higher� during� board� bending� or� under� any�

�other� stressful� condition.�

�Continued� on� the� following� page.�

�147�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

H-22-3A

DIAL SCALE 15 TURN CONCENTRIC

H-23-6M

DIAL SCALE 15 TURN CONCENTRIC

H-26S

SIDE BRACKET FOR MODEL 3250/3252

H-46-6A

COUNTING DIAL 0-20 TURNS

H-83P

RETRO FIT PANEL MNT HOLDER

H472K47X7RL6VJ5R

CAP CER 4700PF 500V 10% RADIAL

HA55L-4523500LF

INDUCTOR POWER 50UH

HB01U05S05YC

CONV DC/DC 5V 200MA UNREGUL

相关代理商/技术参数

GRM43DR61E106MA12L

制造商:Murata Manufacturing Co Ltd 功能描述: 制造商:Murata Manufacturing Co Ltd 功能描述:CAP,CERAMIC CHIP,10UF,25VDC,20%,SMD,1812-CASE

GRM43DR71H155KA01L

功能描述:CAP CER 1.5UF 50V 10% X7R 1812 RoHS:是 类别:电容器 >> 陶瓷 系列:GRM 标准包装:4,000 系列:- 电容:1000pF 电压 - 额定:50V 容差:±10% 温度系数:X7R 安装类型:表面贴装,MLCC 工作温度:-55°C ~ 125°C 应用:自动 额定值:AEC-Q200 封装/外壳:0805(2012 公制) 尺寸/尺寸:0.079" L x 0.047" W(2.00mm x 1.20mm) 高度 - 座高(最大):- 厚度(最大):- 引线间隔:- 特点:- 包装:带卷 (TR) 引线型:-

GRM43DR71H155MA01L

功能描述:CAP CER 1.5UF 50V 20% X7R 1812 RoHS:是 类别:电容器 >> 陶瓷 系列:GRM 标准包装:4,000 系列:- 电容:1000pF 电压 - 额定:50V 容差:±10% 温度系数:X7R 安装类型:表面贴装,MLCC 工作温度:-55°C ~ 125°C 应用:自动 额定值:AEC-Q200 封装/外壳:0805(2012 公制) 尺寸/尺寸:0.079" L x 0.047" W(2.00mm x 1.20mm) 高度 - 座高(最大):- 厚度(最大):- 引线间隔:- 特点:- 包装:带卷 (TR) 引线型:-

GRM43DR72A155KA01L

功能描述:多层陶瓷电容器MLCC - SMD/SMT 1812 1.5uF 100volts X7R 10% RoHS:否 制造商:American Technical Ceramics (ATC) 电容:10 pF 容差:1 % 电压额定值:250 V 温度系数/代码:C0G (NP0) 外壳代码 - in:0505 外壳代码 - mm:1414 工作温度范围:- 55 C to + 125 C 产品:Low ESR MLCCs 封装:Reel

GRM43DR72A155MA01L

功能描述:多层陶瓷电容器MLCC - SMD/SMT 1812 1.5uF 100volts X7R 20% RoHS:否 制造商:American Technical Ceramics (ATC) 电容:10 pF 容差:1 % 电压额定值:250 V 温度系数/代码:C0G (NP0) 外壳代码 - in:0505 外壳代码 - mm:1414 工作温度范围:- 55 C to + 125 C 产品:Low ESR MLCCs 封装:Reel

GRM43DR72A334KW01L

制造商:Murata Manufacturing Co Ltd 功能描述:

GRM43DR72A474KA01L

功能描述:多层陶瓷电容器MLCC - SMD/SMT 1812 0.47uF 100volts 10% RoHS:否 制造商:American Technical Ceramics (ATC) 电容:10 pF 容差:1 % 电压额定值:250 V 温度系数/代码:C0G (NP0) 外壳代码 - in:0505 外壳代码 - mm:1414 工作温度范围:- 55 C to + 125 C 产品:Low ESR MLCCs 封装:Reel

GRM43DR72A474KW01L

制造商:Murata Manufacturing Co Ltd 功能描述: